As many as 105 million people in the U.S. drink water from systems exceeding the new standards for per- and poly-fluoroalkyl substances (PFAS), also known as “forever chemicals.” PFAS are linked to a myriad of harmful health effects, including reproductive health issues, developmental delays in children, increased cancer risks, weakened immune responses, hormonal interference, and elevated cholesterol levels. This, combined with the new regulations, has intensified the race to purify PFAS from drinking water.

To eliminate PFAS from groundwater, innovative technologies for destroying these chemicals must be paired with effective methods to concentrate and contain them. A research team led by assistant professor Xitong Liu of the Department of Civil and Environmental Engineering at GW’s School of Engineering & Applied Science (GW Engineering) made a promising advance in furthering the understanding of polymer-coated colloidal activated carbon (CAC) in the in-situ groundwater remediation for treating PFAS contaminant. This work is detailed in the study “Polymer Coatings Affect Transport and Remobilization of Colloidal Activated Carbon in Saturated Sand Columns: Implications for In Situ Groundwater Remediation.”

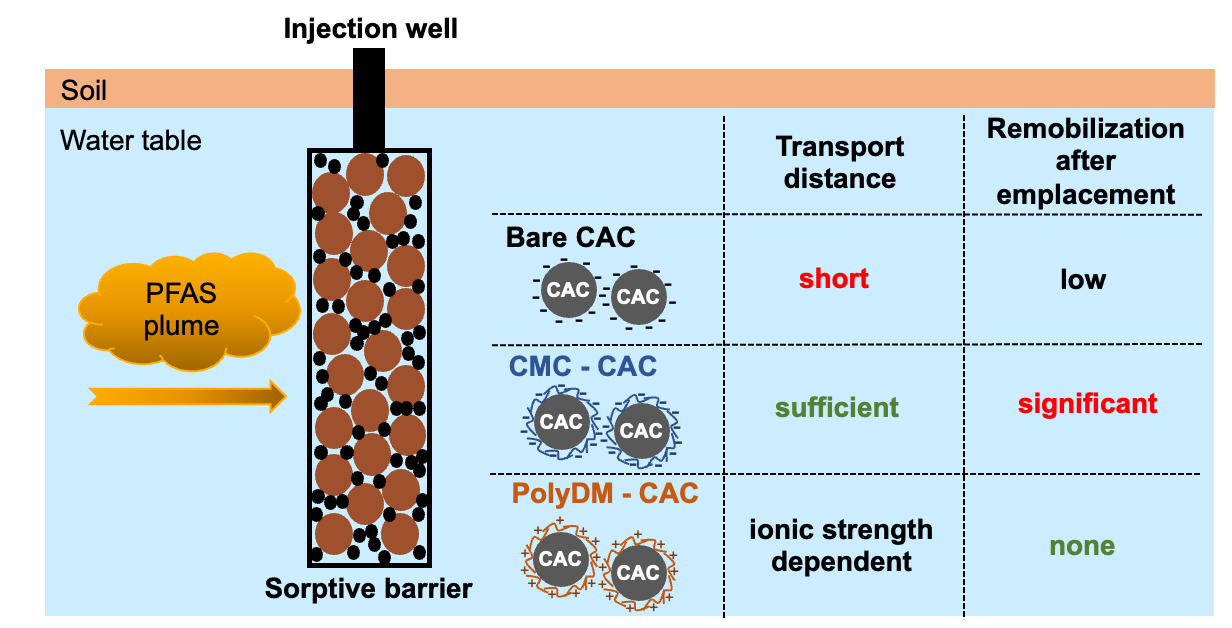

Due to its excellent absorption capacity, CAC is expected to reduce PFAS levels by forming a sorptive barrier in the subsurface. The small size of these particles allows for direct injection into aquifers, making CAC a promising technology for in-situ groundwater remediation. However, there are still questions about how far the particles can travel during delivery and the risk of them migrating away from the barrier once in place. The mobility and remobilization of CAC significantly influence the efficiency and longevity of the sorptive barriers.

“So far, there has been limited research focusing on the phenomenon of remobilization of CAC as a sorptive barrier in groundwater remedies, which influences the longevity of sorptive barriers,” Xun Guan, the first author of the paper and Ph.D. candidate at GW Engineering, stated.

The research team examined the polymers carboxymethyl cellulose (CMC) and polydiallyldimethylammonium chloride (PolyDM), focusing on how each coating affects CAC deposition in quartz sand and to what extent changing groundwater ionic strength (IS) causes them to move again. They hypothesized that polymer coating and IS coupling would regulate the remobilization behaviors of CAC, which their findings confirmed.

The results show that both polymers can improve the stability of CAC, but CMC-modified CAC proved best for improving mobility. CMC-CAC particles showed high mobility in a wide IS range, making it favorable for large-scale CAC delivery. The mobility of PolyDM-modified CAC was high at low IS (0.1 mM) but greatly reduced at high IS (100 mM).

Notably, a significant amount of CMC-CAC particles were released when a low IS solution was introduced after deposition at high IS. In contrast, PolyDM-CAC did not remobilize following deposition due to its favorable interaction with quartz sand. This suggests that PolyDM is the preferred stabilizer for remediation sites with significant IS fluctuations.

“The CAC transport and remobilization behavior influences the CAC barrier’s longevity. Thus, our study provides useful insight and guidance for improving the efficiency and longevity of the CAC sorptive barrier used in in-situ groundwater remediation for treating PFAS,” Guan said.

Published in Environmental Science and Technology (ES&T) in May, the study highlights the importance of polymer coatings and solution chemistry in CAC transport. It offers valuable insights for designing in-situ CAC remediation with enhanced delivery efficiency and longer-lasting barriers. As national and international efforts to address PFAS contamination continue, the team’s findings contribute to the initiative of developing effective and sustainable groundwater remediation technologies.